HDPE films

Home Page / About us / Production / HDPE films

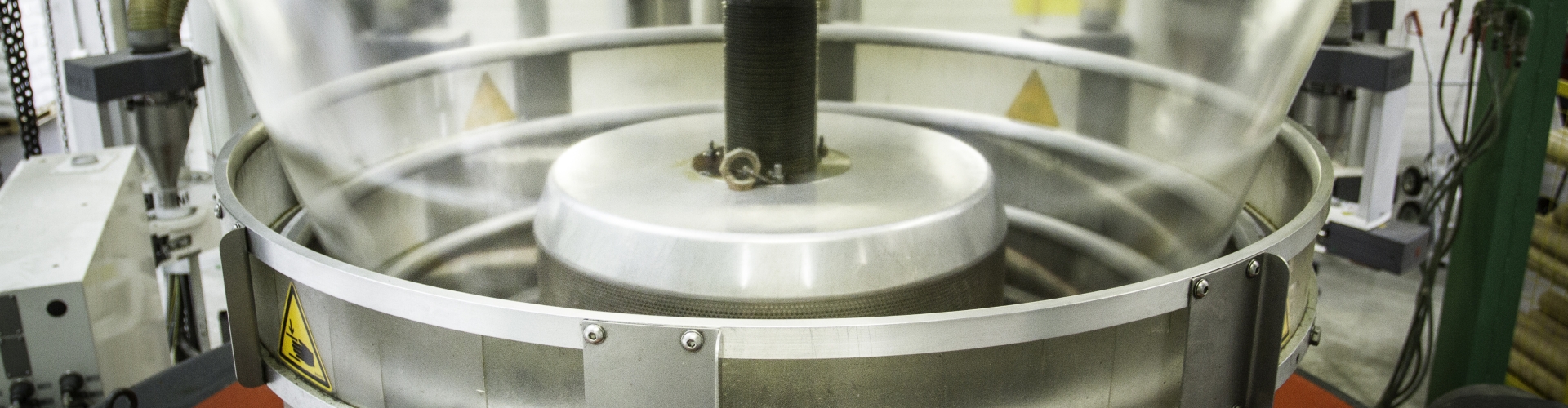

The name of these films, which are known especially under the abbreviation HDPE (or possibly PE-HD), means high-density polyethylene. It is produced under low pressure and its chains are linear. HDPE films are manufactured in the GRANITOL company by using the technology of blowing (blown film) of high-density polyethylene.

HDPE was invented in the 1950s and its mass use began in the 1970s. At that time GRANITOL Moravský Beroun was the only company in Czechoslovakia to produce HDPE films, under the trade mark MIKROTEN® (production since 1976). This led consumers to call HDPE films mikroten.

The name mikroten became a generally acknowledged synonym for HDPE films.

HDPE films are used for the packing of a broad range of products, for the production of boil-in bags and of insulating boards, and as a semi-product for the manufacture of welded products.

HDPE films are marked with this recycling symbol.

Properties of HDPE films

Films made of HDPE are noted for their characteristic rustle and milky colouring and they are odourless. By adding colour concentrates a lot of colour variants can be achieved and by means of additives films with the desired properties can be produced. Unlike LDPE films, their structure is duller, their strength is higher, they are hazier, and they are not shrinkable. The thermal endurance of HDPE films is from −50 °C up to +110 °C. Under everyday conditions of use HDPE films are resistant to most chemical substances, they do not cause corrosion of the products packed in them, and they can be welded. They have minimum permeability of water vapours and smells, and they transmit oxygen, fats, and aromatic substances in a very limited amount. Generally, HDPE films are more chemically resistant, which is given by their structure.

In the natural variant, HDPE films are suitable for direct contact with foodstuffs, the colour variants only if the pigment content is within the concentration defined by the producer. HDPE films are environmentally unobjectionable and recyclable, and they can be disposed of in landfill or by combustion in which no substances harmful to the environment are released.

Use of HDPE films

- packaging of a wide range of products

- liners for paper bags

- separating layer of bitumen boards

- films for the manufacture of boil-in bags

- semi-products for the manufacture of bags, T-shirt bags, and sheets

- semi-product for the manufacture of advertising carrier bags

- semi-product for printing

Possible treatments of HDPE films

- printing with flexographic print up to 10 colours

- ionisation (surface treatment necessary before printing)

- perforation

- punching

- treading

- permanent antistatic agent (permanent reduction of the electrostatic charge of the film)

- antiscratch treatment (protection of the products packed in them from getting scratched)

- antistatic treatment (prevents the "charging" of the film with static electricity)

Quick Contact

GRANITOL akciová společnost

Partyzánská 464

793 05 Moravský Beroun

GRANITOL akciová společnost

Partyzánská 464, 793 05 Moravský Beroun

Phone: +420 554 780 221, E-mail granitol@granitol.cz

Souhlas s cookies

© Copyright 2024, GRANITOL akciová společnost

Tvorba www stránek Winternet