LDPE films

Home Page / About us / Production / LDPE films

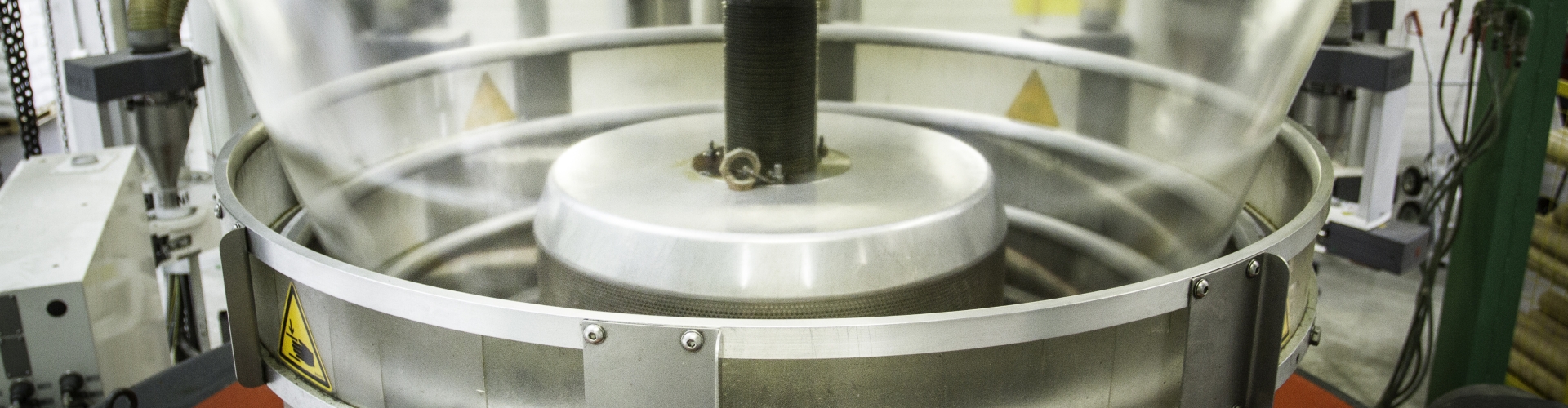

The name of these films, which are known especially under the abbreviation LDPE (or possibly PE-LD), means low-density polyethylene. It is produced under high pressure and its resultant structure is branched. In the GRANITOL company LDPE films are manufactured by using the technology of blowing (blown film) of low-density polyethylene or a mixture of polyethylene and other additives. An advantage of this technology is the possibility of producing shrinkable LDPE films, or, on the contrary, films with minimum shrinkage, according to the client’s needs. LDPE is frequently used in the production of multi-layer or so-called coextruded films.

LDPE films are the most frequently used type of films and in Czech they are known especially under the colloquial name igelit (professionally, this is a wrong name because the word igelit is the original name for films made of polyvinylchloride PVC).

The GRANITOL company started the production of LDPE films as early as in 1967 and on the market these films are known under the registered trade mark GRANOTEN®.

Thanks to their properties, LDPE films are suitable for the packing of a broad range of goods, for the production of group and transport wrappers, for overlaying, and also as a semi-product for the production of welded products.

LDPE films are marked with this recycling symbol.

Properties of LDPE films

The films made of LDPE are clear, flavourless, and odourless. A lot of colour variants can be achieved by adding colour concentrates, and films with the desired properties can be produced by means of additives. The thermal endurance of LDPE films is from -50 °C up to +85 °C. Under everyday conditions of use LDPE films are resistant to most chemical substances and they have minimum wettability and good electrical insulating properties.

Clear LDPE films are suitable for direct contact with foodstuffs; the coloured variants are suitable only if the pigment content is within the concentration defined by the producer. LDPE films are environmentally unobjectionable and recyclable, and they can be disposed of in landfill or by combustion in which no substances harmful to the environment are released.

Use of LDPE films

- heat-shrinkable films for group packaging of goods

- packaging of magazines, insert printing

- films for personal hygiene

- films for the building industry (palletising films and stretch hood)

- waterproofing films for the building industry

- films for agriculture (e.g. films for the packaging of silage, substrates etc.)

- production of adhesive films for surface protection

- manufacture of covers for various applications

- semi-product for the manufacture of bags, T-shirt bags and sheets

- semi-product for printing

Possible treatments of LDPE films

- printing with flexgraphic print up to 10 colours

- ionisation (surface treatment necessary before printing)

- perforation

- punching

- UV stabilisation (film treatment that prevents degradation of the material as a result of UV radiation)

- antistatic finish (prevents the "charging" of the film with static electricity)

- antiblock finish (prevents blocking - sticking of the foil)

- flame retardation by adding fire retardant or extinguisher (additive reducing the flammability of polymers)

Quick Contact

GRANITOL akciová společnost

Partyzánská 464

793 05 Moravský Beroun

GRANITOL akciová společnost

Partyzánská 464, 793 05 Moravský Beroun

Phone: +420 554 780 111, E-mail granitol@granitol.cz

Souhlas s cookies

© Copyright 2025, GRANITOL akciová společnost

Tvorba www stránek Winternet